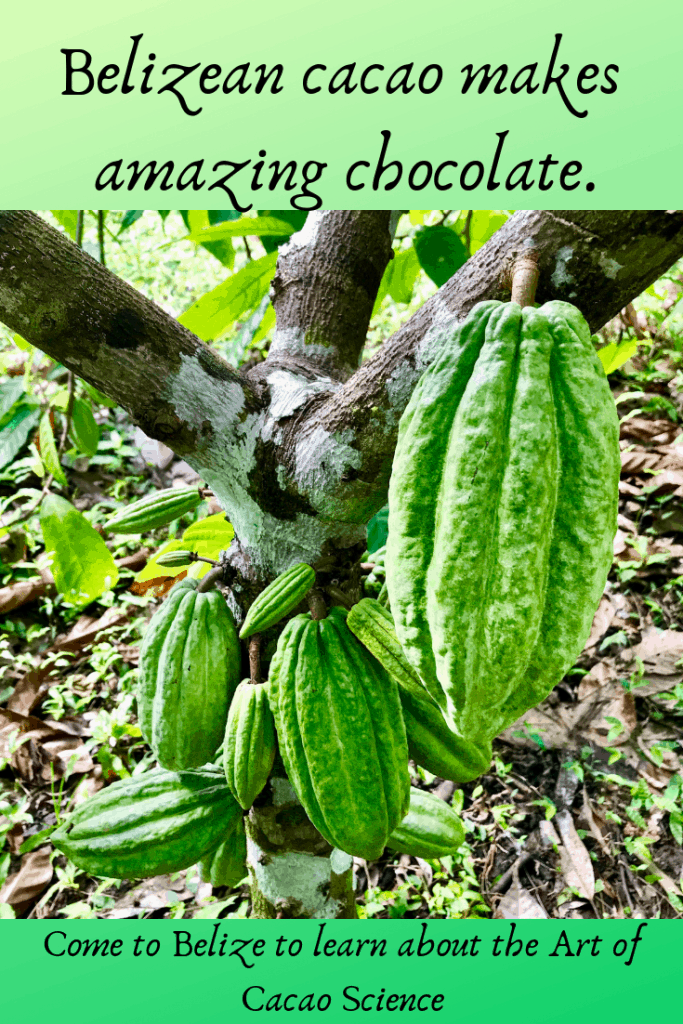

I was thrilled to receive an invitation from the Peini Cacao Plantation Ltd. based in the Toledo District of southern Belize, to come and learn about their operation. The Peini Cacao Plantation is an integral part of AgroNosotros, an international company that operates as International Coffee Farms in Panama and the Belize Cacao Consortium in Belize, with 137 acres of its own on which it grows and processes cacao as Peini Cacao Plantation and buys raw cacao beans from 204 small cacao growers throughout the Punta Gorda region, processes the cacao to its specifications, and sells it abroad as the Belize Cacao Consortium.

It sounds complicated, but the purpose of the consortium is to raise the standard of Belize’s processed cocoa beans and also raise the standard of living for the Mayan farmers who have been growing cacao for generations for their own consumption, but had never modified their practices to allow for international standards required to export their beans and create the best possible chocolate from them.

Through its Socially Responsible Program and relationship with the Na’Lu’Um Cacao Institute–a non-profit association of local Mayan cacao farmers–20% of Peini Cacao Plantation profits are dedicated to supporting cocoa families and assisting them in gaining access to cacao saplings that will help raise the quality of the cocoa they produce and the money they can earn from it.

the art of cacao science requires a skilled team

David Sewell–founder of Agro Nosotros and the Belize Cacao Consortium–and his team at Peini Cacao Plantation took us on a multi-stop tour that explained every step of their cacao operation and their “art of cacao science.”

Most cacao farms in Belize are small, at just 31.2 acres. Each farm has an average of 450 trees. Through Peini Cacao’s Socially Responsible Program, farmers are given four-month old cacao saplings for free and can purchase additional saplings at a very reasonable cost ($2 each at time of my visit.)

Feliciano Pop is the farm manager for Peini Cacao. He uses Mayan tradition combined with cacao science to grow fine flavour organic cacao. Only the largest beans found in the centre of the pod are used to create new seedlings, planted in naturally composted local black soil. Before the beans are planted, they are washed with cold water to remove the pulp. They are then placed on banana leaves and covered with sawdust to help them retain moisture while they germinate. In 3-4 days, germination has taken place and the seeds can be planted in the bio-degradable black plastic bags (shown above) where they will stay until they are planted on the farms at 4-5-months-old.

With 3,000 millimetres of annual rainfall that provide an ideal cacao-growing climate in southern Belize, farmers can appreciate a perpetual (not seasonal) harvest of pods. They don’t need to plant shade trees for the delicate cacao seedlings, and can therefore use a 10 foot x 10 foot ratio in spacing their plants. Mayans believe that the moon has a lot to do with growing cacao, and that the best trees are produced when planted during a full moon cycle. With the perfect climate and soil, what are the biggest challenges to cocoa production in Belize? Woodpeckers and squirrels both enjoy the sweet pulp found inside the cacao pods.

After the pods are harvested, the cacao beans are fermented–a process that is closely monitored by the staff at Peini Cacao Plantation. The beans are fermented for seven days, during which time 20 beans are cut open daily and tested to make sure the beans are progressing as desired. Perfect fermentation is an integral part of developing the full flavour of the beans. The next step is sun-drying of the beans.

After the beans have been dried, they are hand sorted according to size and bagged in 110-pound burlap sacks, where they can be stored up to two years without affecting the quality. When orders are received, the cocoa beans are shipped to chocolate makers around the world, where they are roasted and made into delicious Belizean chocolate. My next post will highlight some of the different processes used in making chocolate in Belize.

On May 9-12, 2019, Peini Cacao Plantation Ltd. hosted the first ever Sustainable Specialty Agriculture Symposium (Peini Cacao Symposium) in Punta Gorda. They brought together international speakers in an effort to revitalize the Belizean cacao and chocolate industry. This event is entirely separate from the Belize Chocolate Festival, which I mention in next week’s post about Belizean chocolate. Please join me then for much more about the wonderful world of Belizean chocolate.

I always enjoy your stories about the search for chocolate. What a wide range of experiences. Always fun to read – whether you are trekking through the jungle, going to a store in Ottawa or taking a chocolate bath. Keep searching and writing!

Thanks so much, Bruce! It’s great knowing that my chocolate travels are hitting the mark with you. I love what I do and every adventure adds new experiences that I can share with my readers. Stay tuned with chocolate tales from Vegas next month! 🙂

How interesting to learn about cocoa. I didn’t know Belize was known for their chocolate. It reminds me of when I worked in my corporate job and our company owned Godiva. I went on a tour of the cocoa bean factory. It was fascinating.

Hi, Judy! Thx for stopping by. Yes, it’s really interesting to tour a cocoa plantation and chocolate factories. It really increases your appreciation for the amount of effort necessary to create our beloved chocolate. 🙂

Your posts are always so informative! I learn something new about chocolate every time I read one of them. I didn’t know the cocoa beans could last two years and that they’d be sent throughout the world to become Belizean chocolates!

Thx for the compliment, Debbie. I always learn something new on every chocolate trip I take. I’m glad you’re enjoying the journey with me. ❤️

I love the idea that squirrels and woodpeckers enjoy chocolate just as much as humans do!

Hi Karen. Woodpeckers, squirrels, rats & other vermin love the sweet pulp that contain the beans of the cacao pods. It does create a challenge for cocoa growers.

The process for growing and harvesting cacao is so interesting. It makes me wonder how someone figured this out in the first place.

Indeed, Donna. But it has been done slowly, over the centuries. The Mayans certainly didn’t make modern-day chocolate. They mostly drank their cacao in a hot or cold thin, but zesty elixir. It was the Europeans (specifically the Spanish) who had already been fermenting grapes to make wine, who made the connection to cocoa and started fermenting the cocoa beans to develop their full flavour and make it into chocolate. 🙂

Sadly, I don’t. Actually, I think the one bar that made it home had chile in it. That one survived because I can’t eat chile.

Great article! I got to visit a cacao plantation in Grenada and we drank cacao tea that was amazing! It’s such and interesting process.

Yes, Grenada is a fabulous destination for chocolate travel and exploring cocoa culture. Did you visit Belmont Estate of Crawfish Bay?

I enjoyed visiting the Peini Cacao Plantation in Belize with you. It does seem that the world’s supply of fine chocolate is limitless.

Hi Carole and thanks for your comment. There are so many amazing places to enjoy chocolate travel and explore cocoa culture. That’s how come I’ve been doing it for 10 years! 🙂

They live close to the coast and not far from Belize City.

That is where I have friends living, too! Here is a post about that visit: https://chocolatour.net/exploring-the-belize-city-area/. Perhaps you would like to send your friends the link. They may know Bob and Heather! 🙂

Doreen, you have some of the most amazing adventures. Getting a firsthand look at the entire process certainly helps truly appreciate the final product. We have friends who live in belize, so it looks like a visit is in order.

Hi Jeff. I’ve done a whole series of posts on Belize from north to south. Where do your friends live?

When you see the extent of what goes into growing cacao plants and making the harvest, it gives you a new appreciation for the cost of really good chocolate. And, of course, makes me want really good chocolate!

Hi RoseMary and thanks for your comment. Yes, cocoa is a difficult crop to grow, and equally difficult and time intensive to properly process. Which is why indeed, good quality craft chocolate is quite expensive. But as we only need a small amount to be satisfied, it doesn’t work out to be that expensive on a per serving basis. I hope you’re making a handcrafted bar last more than one serving! 🙂

Hi Doreen. It’s been a while since I’ve made it to your site! (internet here limits what I can get done before I’m without) I’m glad that I was able to read this post. Who knew that chocolate could be such an interesting topic? Thanks for explaining where it comes from and processed. I hope to read more when I get back home.

Hi Judy and thanks so much for dropping by. I’m glad you enjoyed the post. There is SO much to learn about the world of chocolate and cacao culture.

Ever since I met you at the Chocolate Festival in Honolulu, Hawaii and heard you speak about chocolate, and then read your book, Chocolatour, A Quest for the World’s Best Chocolate, I’ve made it a point to visit cacao growers whenever possible on our travels. We had a chance to buy local chocolate in Ecuador as gifts. I’m embarrassed to say that none of it made it home.

Thanks for your comment, Suzanne. I’m so glad I have inspired you in your chocolate travels. And, yes. Ecuadorian chocolate really is quite delightful. Do you remember what kind you ate?

Sadly, I don’t. Actually, I think the one bar that made it home had chile in it. That one survived because I can’t eat chile.

Super interesting Doreen! I like that they are all working together to improve the likelihood of success. I knew squirrels were a problem for crops but I never thought about the woodpeckers being pests too.

Hi Sue and thanks for your comment. I learn so much every time I engage in #cocoaculture. Visiting cacao farms is always enlightening and is different in every country. I can’t wait for my next adventure to present itself! 🙂

Thanks for explaining the science and showing how much of an art it is also. It is also great that you always mention the Mayan roots of cacao. We always celebrate that every time we have mole sauce here in Mexico.

Hi Carol and thanks for your comment. Yes, the Mayans played and continue to play a big role in growing cacao and developing a strong #cocoaculture. I, too, love Mole and hope that I will soon get to Oaxaca for some more authentic Mexican #cocoacuisine.

Janet, the science of bean fermentation is fascinating and requires a trained eye to get it just right. The Mayan fermentation expert we met at Peini was a real pro. And the drying table pictured at the end of Doreen’s post is quite a marvel compared to other ones we’ve seen on our journeys together, though Doreen has probably come across equivalents elsewhere.

Virginia, thanks for your comment. Yes, I have seen an excellent cacao growing and processing operation in Mexico that I’ve written about previously. That is the Belcolade farm in the Yucatan. They’re not using technology as advanced as what we saw at Peini, but they are experts at what they are doing.

Thanks Doreen for explaining the process. I also find it interesting to see the different colors of cacao. Would every fermented bean be this purple color inside or only Belizean beans? I’m assuming soil etc. affects color.

Hi Janet and thanks so much for your comment. I do think these are the most purple beans I’ve seen during the fermentation stage, although they will change colour each day as the fermentation stage progresses, so it’s mostly a matter of timing.